Chemical &Mechanical Planarization

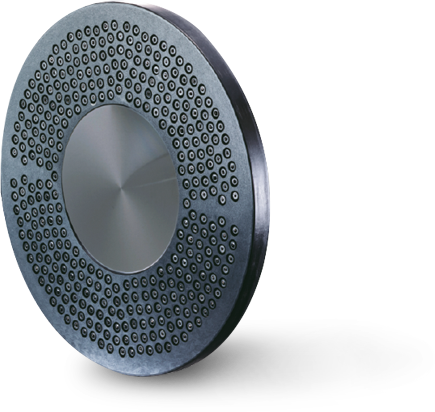

CMP conditioner

During the semiconductor wafer lamination process,

excellent wafer top surface flatness is required to enable continuous lamination work.

To do this, CMP pads must maintain precise flatness, so CMP conditioners are needed.

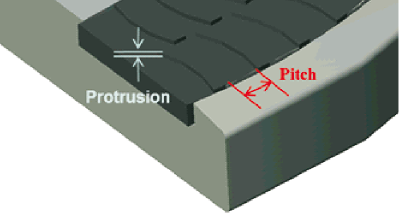

Our CMP conditioner can minimize the damage of the CMP pad and extend its life through

the most advanced diamond shape and arrangement.

| classification | shape | substrate material | Features |

|---|---|---|---|

| DiaGridⓇ |

|

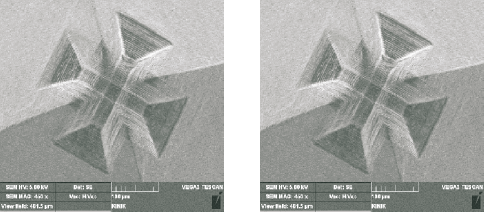

metal substance | ·excellent diamond Combination ·Higher diamond protrusion (over 50% of each crystal): results in Better circulation of slurry and more optimized pad textures ·Unique mating surface profile to reduce micro scratches |

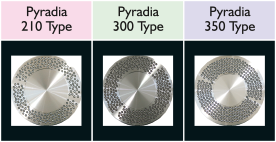

| PyradiaⓇ |

|

metal substance | ·Adjustable for superior leveling ·with precision control of tip height, both cutting rate and pad roughness can be controlled. |

O-PyradiaⓇ |

|

Polymeric substance | ·Metal free ·O-pyrradia retains the advantages of original pyrradia and does not produce metal ions during the dressing process. |

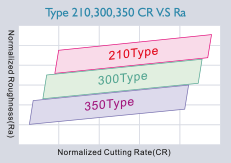

PyradiaⓇ

TH control

the protrusion of stick can be controlled good leveling.

with precision control of tip height, both cutting rate and pad roughness can be controlled.

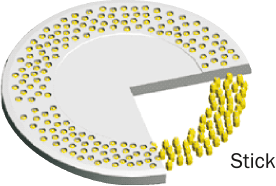

Diamond sticks quantity

A large amount of diamond stick effectively reduces the Ra of the pad by reducing the penetration depth.

A small amount of diamond stick has a deeper penetration and the Ra of the pad is higher.

| Schematic diagram: pad surface roughness after dressing | ||

|---|---|---|

|

Type1 : equal leveling ˙ Same leveling˙ Small Ra ˙ Smooth pad surface |

|

|

Type2 : 2nd level leveling ˙ Medium Ra˙ weak roughness pad surface |

|

Type3 : 3nd level leveling ˙ Large Ra˙ roughness pad |

|

O-PyradiaⓇ

˙ TH control

˙ Diamond sticks quantity

˙ Metal Free

Pyradia retains the advantages of original Pyradia and does not generate metal ions during the dressing process.

| FRT 2D | FRT 3D | Profile | Waviness | |

|---|---|---|---|---|

| 50 ℃ |

|

|

|

|

| 100 ℃ |

|

|

|

|

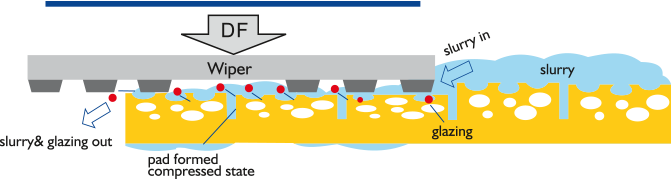

CVD-W

The design of the wiper is to compress the pad with the slurry flow to remove the glazing from the pores. The main function of the wiper on the soft pad is cleanliness, and the cutting ability is very weak. Therefore, the life of the pad can be reached several times.